Why Efficiency In Multi-Modal CGT Manufacturing Is About Execution, Not Just Cost

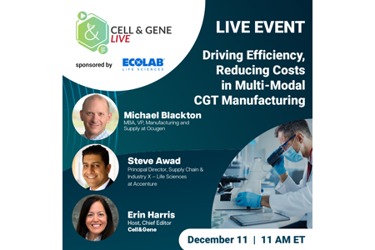

By Erin Harris, Editor-In-Chief, Cell & Gene

Follow Me On Twitter @ErinHarris_1

If cost is no longer the primary differentiator in CDMO selection, what actually defines efficiency in multi-modal cell and gene therapy manufacturing today?

That question sat at the center of our Cell & Gene Live, Driving Efficiency, Reducing Costs in Multi-Modal CGT Manufacturing, when I had to opportunity to talk to industry leaders, Steve Awad, Principal Director, Supply Chain & Industry X — Life Sciences, Accenture and Michael Blackton, MBA, VP, Manufacturing and Supply at Ocugen. Our conversation explored how developers and CDMOs are navigating multi-modal manufacturing decisions, balancing cost, capacity, risk, and long-term commercial viability.

Consolidation Versus Specialization in a Multi-Modal World

Our discussion opened with a fundamental question facing today’s developers: whether to consolidate multiple modalities under a single CDMO or maintain separate partners for each platform. From the innovator’s perspective, Blackton emphasized that capability is the starting point for any outsourcing decision. A multi-modal CDMO can offer advantages in speed, regulatory consistency, quality systems alignment, and supply chain simplicity but only if the technical depth truly exists. Without demonstrated expertise across modalities, consolidation can backfire, creating delays instead of efficiencies. When the capability is real, however, shared practices and aligned strategies can remove months from development timelines.

Awad echoed that developers are taking increasingly nuanced approaches. He shared that across large pharma and small and emerging biotechs, there is no single outsourcing model. Decisions are shaped by access to capital, internal expertise, and risk tolerance. While cost and capacity still matter, developers are more focused on reducing upfront capital investment, accessing scarce technical expertise, and de-risking scale-up across multiple programs. Wherever feasible, a single partner remains attractive because it simplifies governance, tech transfer, and quality oversight, but Awad noted that many companies still split modalities across specialized CDMOs when depth of expertise demands it.

When Cost Becomes Table Stakes and Execution Takes Over

As our discussion progressed, it became clear that cost alone is no longer a differentiator. Blackton argued that while cost and capacity are table stakes, they are not what drives CDMO selection for advanced therapies. Timeline reliability, technical mastery, and the ability to industrialize processes for commercial supply matter far more, particularly in cell therapy, where small patient populations, short product lifecycles, and scale-out constraints dominate operational thinking. For cell therapies, the entire facility effectively becomes the “bioreactor,” according to Blackton, shifting the question from suite utilization to how many patients the factory can reliably serve. In that context, operational excellence and process robustness come first and cost optimization follows.

Awad reinforced this shift, citing Accenture survey data showing that developers rarely cite price as their primary criterion. Instead, they prioritize technical depth, communication quality, regulatory track record, and long-term risk reduction. Over the past five years, CDMOs have begun differentiating through digital integration, advanced analytics, and emerging uses of AI for process control. What was once a scramble for open manufacturing slots has evolved into a competition around platforms, data, and execution maturity.

Company size also plays a major role. Awad noted that 80–90% of many leading CDMOs’ customer bases now consist of small and emerging biopharma companies. To serve them, CDMOs have expanded well beyond batch execution, offering integrated services spanning process development, QC analytics, GMP manufacturing, regulatory support, starting material development, and even custom software solutions. Alongside these full-service models, specialization is also thriving, with vector-only, cell-therapy-only, and automation-focused providers carving out distinct niches. According to Blackton, consolidation and specialization are advancing in parallel: financial pressures drive mergers, while scientific uncertainty and execution challenges make deep specialization indispensable.

Digital Execution as the New Differentiator

Operational efficiency and digital transformation emerged as central themes when our conversation turned to execution. Awad highlighted digital twins, control towers, and integrated process orchestration as some of the most impactful tools reshaping CGT manufacturing. By building low-code, modular platforms with common data models, developers can stitch together people, machines, and systems into a single operational fabric. This approach replaces fragile, multi-year IT deployments with configurable, scalable solutions that support real-time visibility, automated workflows, and faster release cycles while remaining GMP-compliant.

Concrete examples underscored the impact. In one commercial cell therapy operation, a digital twin of the entire facility, encompassing cleanrooms, equipment, QC capacity, staffing, and batch durations, allowed teams to test “what-if” scenarios and unlock significant throughput gains without expanding the site or changing the process. Simply reallocating staff and rethinking schedules led to measurable capacity increases. In another case, an integrated analytics platform tracking the full vein-to-vein journey revealed hidden bottlenecks across scheduling, QC, and logistics. By addressing queuing and manual handoffs, the company cut turnaround time by roughly 50%, transforming its ability to proactively manage patient supply.

Digital tools are reshaping risk prediction. Moving from retrospective reporting to in-process prediction allows teams to identify trends, anticipate deviations, and intervene before batches are compromised. Both panelists stressed the value of automated quality metrics, trend analysis, and integrated dashboards that provide a single source of truth across operations, quality, and supply chain. In a striking example, Blackton recalled a deviation that remained open for six months because fragmented systems prevented timely decision-making, a failure that modern digital integration can help eliminate.

Looking ahead, emerging modalities such as non-viral and electroporation-based approaches offer promise, particularly by eliminating vectors that introduce safety, regulatory, and contamination risks. However, Blackton cautioned that every new modality introduces its own complexities in raw materials, execution, and clinical translation. Manufacturing, he stressed, remains about executing defined processes reliably, regardless of the platform.

Workforce readiness rounded out the discussion. According to Blackton, technology alone does not make a facility multi-modal, people do. Blackton emphasized the need for deeply trained subject matter experts with modality-specific experience, while also noting practical considerations such as geographic access to skilled operators. Awad added that beyond specialists, CDMOs need a cross-trained layer of systems thinkers: project managers, QA leaders, and operations staff who understand how modalities interact within a shared facility and can manage trade-offs holistically.

In closing, both panelists offered practical guidance for developers evaluating CDMO partners. Blackton urged companies to focus on contamination control, quality system maturity, and whether the CDMO truly understands the sponsor’s program and goals. Awad emphasized proof of execution and resilience, encouraging developers to ask for real performance metrics and to understand governance models for when things inevitably go wrong.