Using X-Ray View To See Optimal Freezing Results

How x-ray views affirm plate-based freezers as spearheaded freezing technology in Biopharma

One of the most critical process steps for biopharmaceuticals is freezing the product in single use bags to sub-zero. No matter if companies are freezing bulk drug substance, mABs or vaccines after the downstream manufacturing process or for cell & gene therapies – either as supplement or as industrialized remedy for patients – freezing causes stress for the product. Therefore, it is of great importance to secure its product quality with advanced freezing technologies.

Once a controlled and scalable freezing process is established, it is possible to be reproduced for both, a small-scale model but also for an industrialized scaled-up manufacturing process.

Design of experiment (DoE) to evaluate freezing technologies.

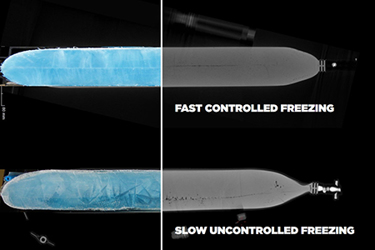

Single Use Support wanted to take a closer look into the single use bags when they’re at frozen state. The aim was to visually compare the interfacial stress of frozen single use bags: How does the bag experience stress in two different approaches of freezing, plate-based freezers and conventional static freezers?

Single Use Support has been made available a computer tomography scan to x-ray both identical single use bags with the only difference of the freezing technology. One bag has been frozen in a plate-based freezer, the other in a static freezer.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Cell & Gene? Subscribe today.