Improving Manufacturing Costs And Patient Safety While Reducing Regulatory Concerns

Apply for the Nanoplasmid AAV Construct Giveaway, and you may be awarded a free plasmid retrofit of your construct into the Nanoplasmid vector system. To apply, submit the form with an optional brief abstract that includes preliminary data and a project proposal. Awards will be granted monthly from March to August. Apply today and discover the Power of Small.

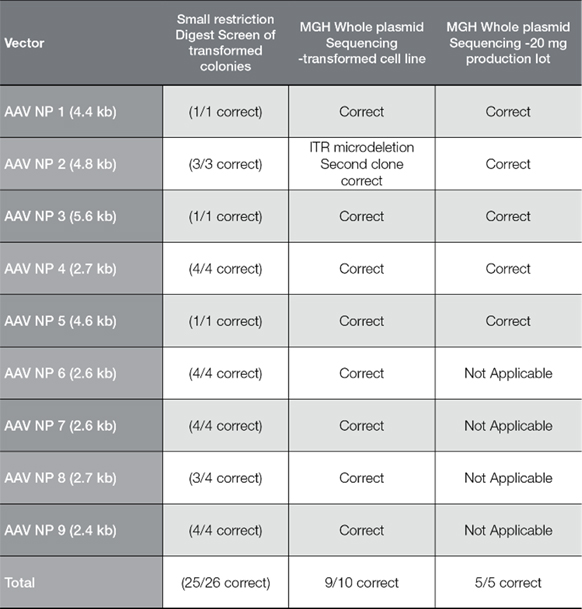

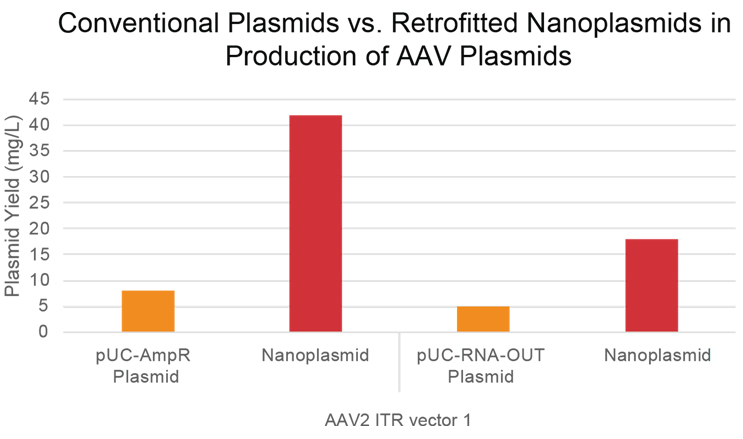

Nanoplasmid’s small backbone (<500bp) and antibiotic-free selection system is designed for cell and gene therapy applications. Its manufacturing benefits include improved plasmid yields as compared to conventional plasmids (Figure 1) and ITR stabilization from the proprietary host strain used to manufacture Nanoplasmid (Figure 2).

Nanoplasmid Host ITR Stabilization

Manufacturing Benefits

Using Nanoplasmid for AAV production can improve plasmid yields with greater ITR stability during manufacturing via the proprietary host strain.

Safety

Nanoplasmid’s RNA-OUT antibiotic-free selection system will eliminate potential marker transfer into patients, reducing the risk of horizontal gene transfer because of its R6K dependent strain propagation.