Forget Lean Cleanroom Construction, Practice Lean Installation

By Chad Smith, Project Development Engineer

Lean is the core of what we do AES, and I want to take this opportunity to explain how we do it.

Lean Construction, as a buzzword, gets a lot of play in the cleanroom industry for good reason. It is an idea that got its start with Toyota in the 1950s to maximize efficiency and eliminate waste in production.

In practice, Lean Construction is a holistic approach that looks at efficiencies across the entire process of building, from architecture to engineering design; from the team hammering nails to the weakest link in the supply chain—Lean encompasses the entire process and each component of the Lean process is maximizes the efficiency of each individual construction project.

As I said, Lean is at the core of what we do at AES, but we do not practice Lean Construction.

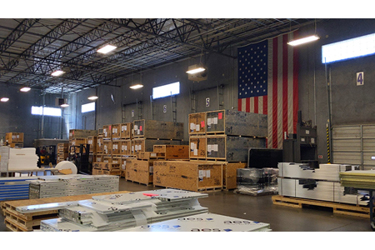

Our modular Faciliflex cleanrooms are never built, so we cannot call it Construction. Every component of our Faciliflex product lines are manufactured in the United States at our clean, efficient factory and installed on your site.

We practice Lean Installation.

What that means for you is that we take out almost all of the risks to your commissioning and manufacturing timeline before our modular walls, ceiling or HVAC components even make it to your site.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Cell & Gene? Subscribe today.