E. coli Plasmid DNA Production Using The DASbox® Mini Bioreactor System

By Nina Schrand and Ma Sha, Eppendorf

In recent years, the need for improved high-yield plasmid DNA production strategies has significantly increased due to its application in the field of messenger RNA (mRNA) vaccines and gene therapy. In order to fulfill the demand for pDNA for use in the biopharmaceutic industry, upstream processing must be optimized to maximize the amount of pDNA produced, which could be accomplished by maximizing the final cell concentration and the average plasmid copy number. As the plasmid titer is directly related to biomass formation, fermentation strategies are based upon increasing total cell density.

An fed-batch fermentation using the well characterized host cell E. coli DH5α results in an enhanced growth rate and the ability to achieve high cell densities with minimal nutrient requirements, with resultant lowered manufacturing costs.

Besides high purity DNA preparation, high concentration is also a prerequisite for optimal production values. The aim of a production process is to limit contaminants such as genomic DNA (gDNA) or RNA and to work towards a unified conformational structure of the plasmid DNA. In previous studies, it has been found that the contamination with gDNA can be significantly reduced by adopting fed-batch culture over a batch culture.

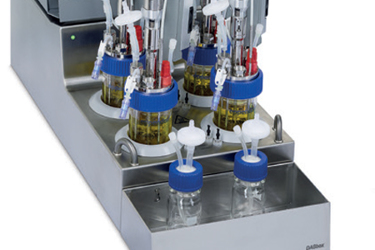

In this study, we outline the feasibility of plasmid production in the Eppendorf DASbox Mini Bioreactor System. Our goal was to increase the overall yield compared to previous studies done with Eppendorf Conical Tubes. We also analyze the effect of a fed-batch process as compared to a batch process.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Cell & Gene? Subscribe today.