ABOUT AST

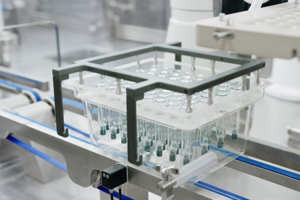

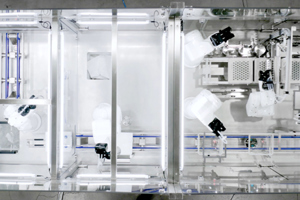

Since 1965, AST has been delivering innovative solutions – many of which were industry firsts and have since become industry standards. AST has always understood that our customers serve demanding and oftentimes unpredictable markets. We also understand that “flexibility is the antidote to uncertainty,” and as your partner, AST consistently seeks to deliver innovative solutions that are robust, yet flexible. AST is a technology leader specializing in advanced aseptic filling and closing systems. Our focus is to provide innovative and flexible products that satisfy the most challenging product and regulatory requirements for the Pharmaceutical and Biotechnology industries. AST’s spectrum of products includes semi-automated to completely automated and integrated cGMP manufacturing systems for processing vials, syringes and cartridges. To discover more about our products please select a product category.

CONTACT INFORMATION

AST

4110 South Washington Street

Tacoma, WA 98409

UNITED STATES

Phone: 253-475-0200

Contact: Brittany Cooksey

FEATURED ARTICLES

FEATURED VIDEOS

FEATURED NEWS

- Aseptic Filling OEM AST To Exhibit At CPHI Frankfurt 2025

- AST Names Industry Veteran Jacob Stephen As Chief Operating Officer

- CDMO Bora Pharmaceuticals Procures New Aseptic Filling And Closing System From AST

- AST Celebrates 60 Years Of Excellence In Innovation And Looks To The Future Of Drug Product Manufacturing

- Aseptic Filling System Provider Announces New Chief Commercial Officer

- AST Will Exhibit New ATMP Fill-Finish Production Line At INTERPHEX Conference 2025

- AST Announces Quick Delivery For GENiSYS® C R&D Small Batch cGMP Filling & Closing System

- AST Announces Additions To Business Development Team

- Ascend Advanced Therapies Procures GENiSYS® C Isolated Filling Systems From AST For Gene Therapy Manufacturing

- Small-Scale Aseptic Filling OEM AST Announces Sean Silvey As New Product Manager

- CURIS System And AST Unite To Redefine Aseptic Fill-Finish Processing Technology

- AST To Exhibit Aseptic Filling Technologies At Advanced Therapies Week

- AST Offers Aseptic Processing Solutions For Life Science Innovators

- An As-Needed Approach To Aseptic Pharmaceutical Fill-Finish Change Parts

- Germfree Laboratories And AST Unite To Redefine Aseptic Fill-Finish Processing Technology

- Quick Delivery Program Supports Critically Ill Patients

- AST Announces New Vice President Of Sales And Marketing

- Aseptic Filling System Leader AST Announces Fall 2022 Exhibition Schedule

- AST Announces Availability Of Quick-Delivery Isolated Fill-Finish Equipment

- Leading Aseptic Filling System Provider AST To Exhibit At ACHEMA 2022 Conference