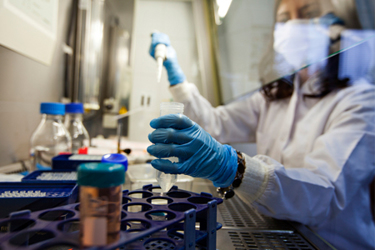

Viral Vector Process Development

From idea to bench and bench to trial, we leverage over a decade of experience in viral vector process development and manufacturing services. We deliver flexible and scalable process development and optimization support that moulds to your needs and keeps commercialization front of mind.

Early Cell Line Development

We support the development of producer cell lines and optimize the viral vector platform for your product. We ensure your process is robust, scalable, and transferable from early phase through to commercial production to simplify your regulatory strategy.

Early Development

- Transient transfection and plasmid system options

- Producer cell line development

- Plasmid design

- Selection of viral vector platform and cell line for vector production

- Reproducible process design with commercialization approach

Process Optimization

Our team guides and optimizes your viral vector development process, ensuring it is repeatable, scalable, and transferable to cGMP manufacturing. We work with you to ensure efficient scale-up, increase titers, reduce development timelines, and lower costs as we support your upstream and downstream process development.

Early Development

- Upstream processing

- Downstream processing

- Proof of concept evaluation runs

- Research cell banks

Non-cGMP Vector Production

- Engineering runs at variable scales for further optimization in the process development lab

Phase I-II cGMP Productions

- Optimized cGMP runs

- Master and working cell bank productions

Easy Scale-Up

We offer flexible non-GMP and GMP viral vector manufacturing capacity and support scale-up for both adherent and suspension platforms. Whether you need to adapt and develop a suspension process or scale an adherent process from research to clinical-grade production, everything we do is meaningfully focused on getting your viral vector to commercialization.

Non-cGMP Production

- Cost-effective process runs before cGMP productions

Phase I-II cGMP Production

- Suspension: ≤ 200L

- Adherent: ≤ 500m2

Controlled Processes

Ensuring quality and efficiency, we develop reproducible, scalable and robust processes in closed systems which also help minimize to opportunities for errors.

Non-cGMP Production

- Further optimization to get to a closed and semi-automated system for vector production.

Phase I-II cGMP Productions

- Aseptic processing using single-use closed systems from upstream processing to fill and finish.

Cell Line & Assay Testing

We accelerate your program with in-house analytical cell line and assay testing, development and qualification tailored to your viral vector and/or gene of interest.

- Lentiviral reverse transcriptase assay

- Replication-competent lentiviruses (RCL) assays

- RNA titers

- Infectious Units assay using flow cytometry

- P24 assay

- Host cell protein

- Host cell DNA detection

- Plasmid DNA contamination

- Endotoxin