The Critical Roles Of cGMP Chemicals And Single-Use Technologies In Cell & Gene Therapy Manufacturing

By Tim Korwan, Director, New Product Development, and Wayne Lynch, Senior Product Manager, Avantor

Cell and gene (C&G) therapies are bringing new hope to patients fighting a wide range of serious and life-threatening conditions. The growing pipeline of C&G therapies, combined with their clinical success rate, has led to expectations from the FDA that the agency will be approving 10 to 20 C&G therapy products a year by 2025.1

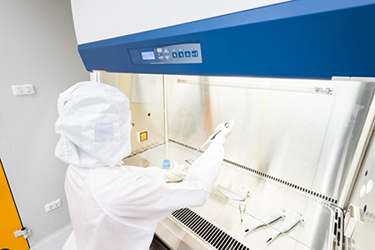

While these products are reshaping the biopharmaceutical industry, they are also creating unique challenges for manufacturers trying to bring them to market. Ensuring these transformative medicines make it to the patients who need them requires risk mitigation strategies that not only improve the quality of raw materials but also facilitate scale-up processes in order to meet global demand.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Cell & Gene? Subscribe today.