Takeda Breaks Ground On New Cell Therapy Manufacturing Facility In Massachusetts

One of the next frontiers for Takeda is accelerating next-generation cell therapies, which promise to build upon the first generation of cell therapies in cancer treatment with the potential to improve safety, efficacy and patient convenience.

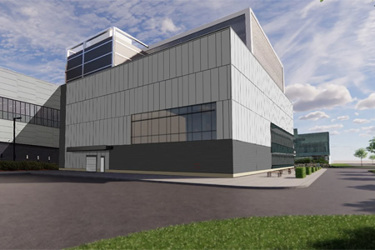

To support Takeda’s focus on cell therapies, we recently broke ground on a new 38,000 square-foot (3,530 square-meter) commercial cell therapy manufacturing facility on our Lexington, Massachusetts, campus. The new $84M facility will be used for the production of oncology and other cell therapies.

Poised to deliver cell therapies globally, the new facility will be compliant with regulations worldwide, including the United States, European Union and Japan. The new ballroom-style facility will have a versatile, flexible footprint, allowing for future expansion to support the manufacturing of multiple commercial and clinical products, with additional capacity to expand the manufacturing space.

The new facility will utilize closed systems, isolator technology and robotics, and the technology will be an end-to-end single use system without the requirement of on-site sterilization. It will also use Takeda’s Enterprise Data Backbone (EDB) to consolidate data from multiple sources and virtual reality (VR) training for operators, so they can learn in a virtual environment before they enter the real facility. These features will enable the facility to ramp up quickly, and make manufacturing processes more robust, reproducible and scalable.

Aligned with Takeda’s goal to reduce greenhouse gas emissions from its operations by 40% by 2025 and be carbon zero by 2040, the building design also incorporates solar panels, heat recovery pumps, electric boilers, energy efficient equipment and eliminates the need for additional fossil fuel burning equipment.

Takeda’s Commitment to Cell Therapy and End-to-End Development

The construction of the new 38,000 square foot facility further builds on Takeda’s commitment to cell therapies. Takeda opened a new 24,000 square-foot R&D cell therapy manufacturing facility in September 2020 at its R&D center in Boston, Massachusetts. The facility provides end-to-end research and development capabilities and will produce cell therapies for clinical evaluation from discovery through pivotal Phase 2b trials.

Takeda’s cell therapy manufacturing facilities foster proactive and deep collaboration between R&D and commercial manufacturing that is critical to developing and delivering next-generation cell therapies faster. Takeda’s Cell Therapy Translational Engine (CTTE) provides product development, automation, engineering, chemistry, manufacturing and control (CMC), data management, analytical and translational capabilities in a single footprint to overcome many of the manufacturing challenges experienced in cell therapy development.

With the new commercial cell therapy and R&D manufacturing sites within a 20-mile radius, insights gained in manufacturing and clinical development can be quickly shared across our teams.

Takeda also produces the first approved allogeneic stem cell therapy, which treats perianal fistulas in adult patients with Crohn’s disease. Takeda has manufactured the therapy since 2018 and plans to expand production from Madrid, Spain, to more sites in Europe, the United States and Japan. In February 2021, Takeda announced the expansion of the cell therapy manufacturing line at the Grange Castle site in Ireland.

Learn more about Takeda’s cell therapy advancements here (https://www.takeda.com/newsroom/featured-topics/accelerating-next-generation-cell-therapies/).

Source: Takeda Pharmaceutical Company Limited