Revolutionizing Lentiviral Vector Manufacturing For In Vivo And Ex Vivo CAR-T Cell Therapies

By Jae Hwang, Senior Scientist; Evan Schlaich, Associate Director, Process Development; Andrew Detzel, Associate Director, Process Development; Chris Nieder, Head of Technical Development; Brian Tomkowicz, Ph.D., Vice-President, Head of R&D and Virology Fellow

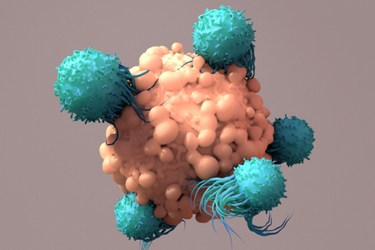

Lentiviral vectors (LVVs) play a critical role in genetic engineering strategies for CAR-T cell therapy, serving as the primary delivery vehicle for stable gene modification. Since the approval of Kymriah® in 2017 — the first CD19-directed, genetically modified autologous T-cell immunotherapy for patients with B-cell precursor acute lymphoblastic leukemia — the field has continued to evolve rapidly. In particular, development efforts are increasingly shifting from traditional autologous ex vivo manufacturing paradigms toward in vivo gene delivery approaches that enable direct T-cell transduction within patients¹.

This paradigm shift significantly increases the demand for LVV manufacturing platforms that are not only scalable and cost-effective, but also aligned with evolving regulatory expectations and designed to ensure safety for systemic administration²,³. As clinical programs advance, the need for robust, industrialized LVV production processes with consistent quality attributes has become increasingly critical.

In this white paper, we explore the current state and future direction of LVV process development, with a particular focus on cost-efficient scalability, manufacturing robustness, and industrial platformization. At SK pharmteco, a robust downstream process has been established to support ex vivo LVV-based CAR-T manufacturing while delivering the high level of quality, consistency, and control required to enable emerging in vivo therapeutic applications.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Cell & Gene? Subscribe today.