PODs: Providing The Flexibility Needed For Advanced Manufacturing Facilities

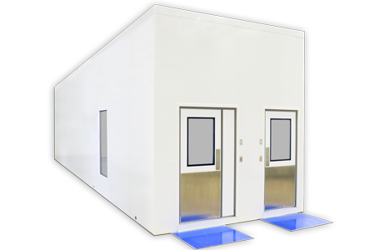

G-CON’s POD technology was invented to address the demand for flexible and expandable controlled cleanroom environments to support the manufacturing of personalized medicines. Since our inception in 2009, G-CON has become the global leader in pre-fabricated modular cleanroom solutions for ATMPs. Our cleanroom PODs are built off site at our center of excellence by a dedicated team within a robust quality system in order to provide the highest level of certainty for project outcomes.

Speed to the clinic and market has been an underlying driver for the ATMP industry, and G-CON has helped many of its clients accelerate the implementation of new facilities by significantly reducing project timelines compared to a traditional on-site construction approach. More recently, agile manufacturing has more important for cell and gene therapy facilities and again, pre-fabricated solutions provide the flexibility and mobility needed to address this critical need.

If you have not spoken to us yet or would like to understand our latest advancements, please contact the G-CON team at sales@gconbio.com to better understand how we can be your trusted partner for your ATMP facilities. We are proud to support our clients in bringing their facilities on line faster and smarter as they continue to develop and launch their life changing therapies and medicine.

G-CON is proud to have supported our clients clinical and commercial ATMP manufacturing facilities. These include:

- AmplifyBio

- Avexis (since acquired by Novartis)

- Codiak

- CytoImmune

- Eli Lilly

- Expression Therapeutics

- Fujifilm Diosynth

- Gencure

- Instil Biosciences

- Janssen

- Marker Therapeutics

- Matica

- Novartis

- Pfizer

- Rubius

- Scorpius BioManufacturing

- Tenaya