PAS-X Universal Connectivity Software: Integration Of Equipment And Automation

Our Plug & Produce solution allows a fast and easy integration of machines and automation systems into a pharmaceutical production environment – a prerequisite for the implementation of many Industrie 4.0 solutions.

Compared to before, workload for integrating a new machine into its production environment can be cut by up to 75%. In other words, the workload will be merely a quarter of what it used to be!

1. Streamlined engineering

The engineering and configuration workload is significantly lower.

2. Less setup errors

The installation of a new machine is easy and therefore extremely reliable, greatly diminishing the likelihood of setup errors.

3. Less qualification effort

Far less qualification effort is needed to satisfy compliance requirements.

4. Reduced project run times

Project run times are reduced as MBRs can be developed independently and in parallel at Level 2 and Level 3 at a very early stage of the project.

Universal connectivity with new standardized interface

Connecting a new machine to the production network used to be highly complex, time-consuming and unproductive. In the future this will be much easier: Thanks to our Plug & Produce solution all it will take is to connect the equipment to the manufacturing IT system via a simple plug – just like inserting a USB flash drive into a laptop. The new machine or automation system then logs on to the PAS-X MES by itself. Our software automatically receives all relevant information for the electronic execution and documentation of the production steps.

Connecting a new machine to the production network used to be highly complex, time-consuming and unproductive. In the future this will be much easier: Thanks to our Plug & Produce solution all it will take is to connect the equipment to the manufacturing IT system via a simple plug – just like inserting a USB flash drive into a laptop. The new machine or automation system then logs on to the PAS-X MES by itself. Our software automatically receives all relevant information for the electronic execution and documentation of the production steps.

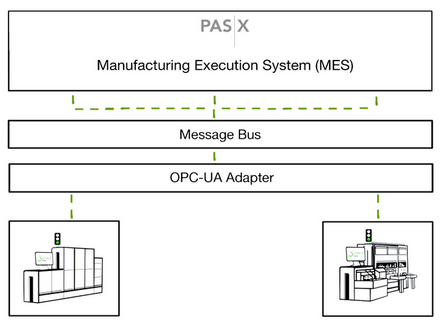

This will be achieved because the machine on the shop floor and Werum’s PAS-X software communicate directly via a new standardized messaged-based interface. The new Plug & Produce interface makes sure that Werum’s software and the machines or automation systems speak the same language.

Plug & Produce: Your entry point to Pharma 4.0

Article in facts, the customer magazine of Medipak Systems

Werum IT Solutions together with the Medipak Systems companies Dividella, Mediseal and Seidenader and other vendors and partners like ISPE is working on a solution for the structured data exchange between the production management software and the equipment in a pharmaceutical plant: “Plug & Produce” is our vision for a new industry standard which will enable the fully networked industrial pharma production – Pharma 4.0 – in the future.

Unique: Completely vendor-independent

What makes Werum’s Plug & Produce solution with PAS-X unique is that it is an open solution, completely vendor-independent. Our solution offers the most universal integration interface available on the market supporting the standardization goals of the ISPE Plug & Produce working group already today. In the future pharma manufacturers will be able to use Werum’s Plug & Produce solution with any smart equipment, DCS or SCADA system.

Together with partners, vendors, pharma companies and organizations like ISPE, Werum is collaborating to establish a message-based interface as an open industry standard, which will be included in Werum’s PAS-X MES software in the future.

Werum and ABB team up for integrated solution

In order to integrate Werum’s PAS-X MES and ABB’s Process Control System 800xA, ABB has added Werum’s Plug & Produce solution to its Manufacturing Operations Management (MOM) solution. The offering called Shop Floor Integration for Life Sciences includes features for automatic parameter assignment and automatic synchronization of 800xA Batch Management recipe procedures and MES.

This automated integration significantly reduces the engineering effort of the integration especially with the high validation requirements in a GMP production environment. Pharma and biotech customers will benefit from simplified operation, faster MBR creation, and a joint deployment and validation approach.

Among the first common customers implementing this new solution is GE Healthcare. At their manufacturing site in Uppsala, Sweden, which has one of the world's largest installed capacities for production of chromatographic resins, GE Healthcare uses the Plug & Produce solution to integrate the automation and equipment level for the production of a chromatography medium.