NK Cell Therapies: How Artiva Biotherapeutics Leverages Its "Manufacturing First" Approach

A conversation with Chris Horan, chief technical operations officer, Artiva Biotherapeutics

Chris Horan is Artiva Biotherapeutics’ chief technical operations officer, leading teams across CMC development, manufacturing, supply chain and quality. We caught up with him to discuss natural killer (NK) cell therapies and Artiva’s experiences and strategies with its candidate, AlloNK.

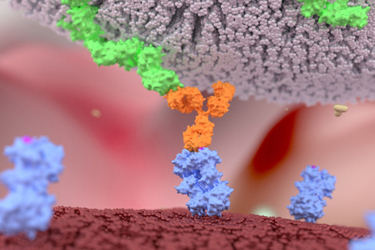

Why do NK cell therapies hold promise in treating autoimmune disease?

What is the biggest technical/scientific challenge of developing NK-based therapies, and what has been Artiva’s experience addressing that challenge?

One of the biggest technical challenges for the NK cell therapy field is related to the much larger market size opportunity in autoimmune diseases, which drives the need to develop a massively scalable “industrialized” manufacturing process. Massively scalable means being able to produce enough product to treat tens of thousands of patients each year or, in other words, potentially hundreds of trillions of NK cells. Industrialized means the product is well characterized and consistent batch to batch and donor to donor and can be produced with operational efficiency.

To address these challenges, Artiva is building on a robust platform developed and refined by our partner, GC Cell, over the past decade. For example, our platform is based upon a combination of preselected cord blood, a proprietary engineered feeder cell, and carefully selected media resulting in robust expansion without exhaustion. With more than 35 clinical-scale batches already produced, we are building on our experience as we work to further increase the inherent scale and COGS advantages of our non-genetically modified process. Across these batches, we established high confidence in consistency, both batch to batch and donor to donor — essential for any allogeneic off the shelf product. We are currently working on scaling up from 50 liters to 200 liters and increasing the cell volume capabilities of the downstream process from purification through filling and cryopreservation.

What are the best practices, or pitfalls to avoid, of cryopreservation?

Cryopreservation of NK cells has historically been a challenge because they consist of a heterogeneous cell population that can be sensitive to the stresses of freezing and thawing. Because it can be challenging, our recommendation is to start developing a robust cryopreservation process early, ideally before the start of clinical studies. Finding the right combination of cell density, freeze media, and controlled rate freezing profiles can take time. Artiva’s process involves a proprietary freeze media and cryopreservation program that yields viable and functional cells after thaw. Importantly, our freeze media is also infusion-ready, simplifying administration by eliminating the need for further processing at the clinic. Cryopreserved AlloNK is viable and active after thawing, with over three years of stability data in hand.

How is Artiva approaching clinical trials of its NK cell-based candidate, since patients need multiple doses?

Proof of concept with autologous CAR-Ts in autoimmune disease demonstrated that a relatively short-lived CAR-T construct, detectable in circulation for around a month, could induce deep B cell depletion but then allow B cells to reconstitute after several months. We are aiming to mimic the same kinetics in our study by giving several doses of AlloNK over the first few weeks.

We established end-to-end cold-chain logistics to manufacture and cryopreserve AlloNK, store it in a central facility, then ship it to clinical sites as needed. It is not uncommon for clinical sites with experience in oncology and cell therapy to have liquid nitrogen storage capabilities. These sites can receive and store multiple doses of AlloNK for future use. In community centers, especially for autoimmunity, sites may not currently have liquid nitrogen storage capabilities, in which case dewar solutions are readily available.

Can you tell us more about Artiva’s “manufacturing-first approach” and how it’s different from the traditional approach? How is Artiva approaching the closed process to minimize any variability?

Artiva was founded based on NK cell platform technology from our partner, GC Cell, a company which has more than 10 years of experience in cell therapy. So, even though Artiva is less than five years old, we believe we have a significant head start in manufacturing — hence “manufacturing first.” Our process is differentiated by its simplicity. AlloNK is not engineered; NK cells are expanded from umbilical cord blood using a proprietary engineered feeder, and there is no transduction step necessary in the creation of master cell bank vials. The finished drug product is cryopreserved in an infusion-ready media with up to 36 months of stability already confirmed.

We utilized GC Cell’s GMP manufacturing to produce AlloNK for our ongoing clinical trials. In addition, we established our own manufacturing capability in San Diego by recruiting a team of experts and building development labs and a relatively modest 9,000-square-foot cGMP manufacturing facility that can produce over 6 trillion NK cells per year at the current scale. San Diego was a clear choice for us based on its thriving cell therapy community and deep talent pool. Over the past several years, we further industrialized the process to improve operational efficiency and sterility assurance. For example, we established fixed passage and harvest windows to enable predictable batch scheduling and closed open process steps to reduce contaminations risks.

About The Expert:

Chris Horan is Artiva’s chief technical operations officer, leading teams across CMC development, manufacturing, supply chain, and quality. Prior to Artiva, he spent nearly 14 years at Genentech, a member of the Roche Group, where he held several leadership positions across technical operations, including as senior vice president, global product and supply chain management for Roche in Basel, Switzerland. In that role, he led a 480-person team supplying all of Roche’s biopharma products worldwide. After that, he was CTO of SanBio as well as Dermira, where he led all aspects of technical operations.