MES Is Still In The CD ROM Era But The Data Architecture Has Moved On

By Ciera Clayton, global change facilitator, BioPhorum

We already know what the architecture of the future looks like: a cloud‑enabled, data‑centric platform designed for continuous evolution, not one‑time installation. We just have not applied it consistently in pharmaceutical/biotech manufacturing.

Consider the evolution of Microsoft Office.1 It has moved from one‑time installs on a CD to a cloud‑native, subscription experience that integrates across Teams, Outlook, OneDrive, and more, with continuous updates and a rich ecosystem of extensions.

In contrast, many manufacturing execution system (MES) deployments still operate like it is 2005: a big install, heavy configuration, then long periods of stagnation punctuated by disruptive upgrades. Industry surveys consistently show that more than half of MES and enterprise resource planning (ERP) customers run two or more versions behind current releases, largely because upgrades are costly, risky, and require revalidation.2 So is there a better way? One that applies the same architectural lessons already embedded in modern enterprise software?

The Architectural Lessons We Keep Ignoring

We do not need to reinvent the architecture; we just need to reapply what we know. The first step is to stop treating MES like a CD‑ROM suite. Consider Microsoft’s original software strategy from the early 2000s: you buy a CD-ROM for a small fee, do a one-time install, and use the software as per the original installation. A decade or so later, Microsoft updated its approach: you could either buy the CD-ROM or adopt a subscription-based model instead, moving away from hardware and onto cloud storage with new features easily added through updates. Over time, this has become the norm, and we now have a new ecosystem of applications. However, when it comes to an MES, we seem to be stuck in the 2000s: we install, configure, and then watch it drift out-of-date almost as soon as it goes live.

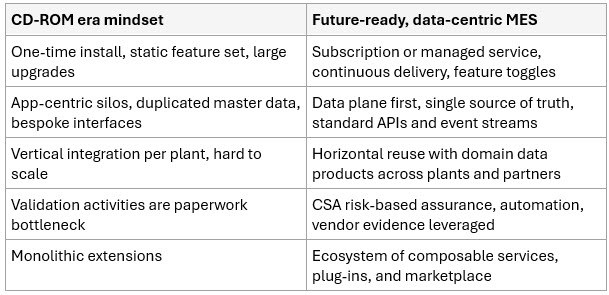

Here is a simple comparison that will resonate with any IT leader or SME:3,4,5,6,7

We must be realistic about the future of MES. If you consider the capital depreciation perspective, organizations are likely to upgrade their infrastructure every seven years, even if OEMs push for three- to five-year refreshes. That means vendors must support backward compatibility while enabling continuous delivery and data‑plane stability. This diverts vital resources (people and money) away from innovation projects — from both the vendors and the biomanufacturers. The good news is that enterprise practice shows servers often run effectively well beyond five years when managed and supported, so the window to modernize the software architecture without constant hardware churn is real.8,9

To achieve an adaptive plant (Digital Plant Maturity Model Level 510) you must invest in the automation value stream, and you must have the entrepreneurial courage to do it. This is a leadership conversation about data enablement and data-centric architecture, not about MES. Due to career progression, our leaders are often not around to see the impact of the changes they make; therefore, they need the entrepreneurial courage to do something different. Most people do not want to be the first; board members are usually looking at a consistent return, not at taking risks, but catching up is considerably more difficult than being the leader. Even if you catch up, you might not be able to surpass those who came before because they are now on cruise control.

What Is Industry Doing Today?

Enterprise application leaders separated applications from the data plane years ago. For example, SAP’s Business Technology Platform and reference architectures formalized a layered model where apps sit on top of integration, data, analytics, and AI capabilities.11,12 Meanwhile, Oracle has popularized data‑centric and data mesh patterns that treat data as a product, with decentralized ownership, streaming, and federated governance.13,14

Zhamak Dehghani (founder of Nextdata and creator of the data mesh concept) called this out in 2019 and has since reiterated that scaling analytics requires domain‑oriented data, self‑serve platforms, and federated governance — not bigger monoliths.15,16 She said, “Treat data as a product, owned by the domain that knows it best, and enable interoperability through a self-serve data platform.”

This principle aligns perfectly with the data-centric MES vision. Instead of duplicating master data across ERP, MES, LIMS, and QMS, we should:

- Decentralize ownership: Let each domain curate its data products (e.g., batch execution, quality events) with clear contracts.

- Enable interoperability: Use open APIs, event streams, and semantic standards (ISA-95, OPC UA) to make data discoverable and reusable.

- Build a self-serve platform: Provide tools for contextualization, governance, and analytics without forcing every integration through a central bottleneck.

Data mesh thinking reinforces the need for MES as part of a federated data ecosystem, not a siloed application stack. This is how we unlock scalable analytics, AI, and adaptive manufacturing.

Process industries have analogous proven constructs. For example, NAMUR Open Architecture adds a secure second channel for monitoring and optimization data in brownfield plants.17,18 At the same time, OPC UA provides secure, semantic interoperability up and down the stack. These are not academic ideas; they are deployed and evolving now.

Meanwhile, major cross-industry vendors are already aligning to this data‑first platform direction:

- A global automation leader has announced a multilayer strategy to unify data across intelligent fields, edge, and cloud, anchored by a unifying data fabric to eliminate hierarchical barriers.19

- A major industrial software provider has expanded cloud‑native SaaS for manufacturing execution and data operations to break silos and accelerate outcomes.20

- A multinational digital engineering platform has demonstrated OT/IT convergence from edge to cloud, enabling AI and executable digital twins through an open approach.21,22

The point is not which logo wins. The point is the architecture. We do not need to reinvent it. We need to apply what already works. With the push to implement AI solutions across the manufacturing landscape, it is important to note that, according to

Andrew Ng, founder of DeepLearning.AI, cofounder of Coursera, and formerly chief scientist at Baidu and head of Google Brain,23 “AI’s next unlock comes from data‑centric practices — systematically engineering high‑quality, consistent data.”

What This Means For AI

Without a data‑centric architecture, AI becomes an expensive toy. When the same fields are redefined across ERP, MES, LIMS, and QMS, models will over‑weight the wrong signals, and you might spend your budget reconciling semantics instead of generating value. This is precisely why Gartner and others champion data fabric designs that use active metadata and knowledge graphs to make distributed data usable, governed, and ready for AI.5,24

It is important to note that everyone wants AI because it is the new shiny thing. But in reality, it is just another tool, and you need the best tools available to give you the most value. Your focus should be on the return on value.

In life sciences, the regulatory environment is also moving in the right direction. The FDA’s final computer software assurance (CSA) guidance emphasizes risk‑based assurance and modern tooling,6 while ISPE GAMP 5 Second Edition codifies agile, cloud, and data integrity by design. The combination of CSA and GAMP 5 lowers the friction to deliver continuously updated, cloud‑enabled MES capabilities.7

What This Means For Integration

Integration in an MES context has historically been treated as a technical exercise, connecting systems through custom interfaces and point-to-point data flows. But in a data-centric architecture, integration is not about the “plumbing”; it is about creating a unified, trusted data fabric that drives business outcomes. The goal is to make data interoperable, contextualized, and actionable across the entire manufacturing ecosystem. This means moving beyond connectivity for connectivity’s sake and focusing on value-driven use cases that empower operators, QA, process engineers, and planners to make faster, better decisions.

A data‑centric MES should make interoperability the default:

- LIMS should pass sample plans and results required for downstream steps and avoid overloading MES with nonessential lab details.

- ERP should synchronize orders, materials, genealogy, and disposition and support co‑products and expiration logic.

- QMS should automate exception routing with severity and enable by‑exception review for near‑real‑time release.

- Historians and control systems should use event frames and contextual tags to stitch execution context with time‑series process data.

We should focus on use cases and personas (e.g., operators, QA, process engineers, planners), not just systems. This is because integration should exist to deliver actionable, auditable outcomes.

What Needs To Change

- Design the data plane first:25 Publish and govern canonical models, events, and metadata; use open standards and APIs to make integration predictable.

- Modularize delivery: Move from monolithic deployments to composable services and MES building blocks that start small and scale.

- Treat recipes and MBRs as products: Provide template libraries, low‑code/no‑code editors, and automated migration tools to reduce effort and error.

- Plan for hybrid and cloud with business continuity:26 Architect production‑critical functions to run locally or in a resilient edge pattern, while noncritical environments (dev, test, training, analytics) live in the cloud.

- Lean into modern assurance: Adopt risk‑based CSA, automate verification, and reuse supplier evidence to accelerate change without compromising compliance.

- Integrate for outcomes, not for integration’s sake:27 Prioritize high‑value interfaces, such as LIMS, ERP, QMS, and historians and design for event‑driven flows, contextualization, and clean handoffs.

- Make change management part of the architecture: Implementation fatigue and cultural resistance are real. Build in rapid wins, role‑based training, and transparent road maps.

- Lead with data enablement, not features:28 The fastest ROI comes from eliminating duplicate definitions and handoffs that slow batch release and tech transfer. Accenture, for example, argues that traditional function‑siloed architectures cap the value of predictive and prescriptive use cases and recommends data‑centric manufacturing system architectures to enable adaptive operations.29,30

- Map change to the BioPhorum Digital Plant Maturity Model:31 Use DPMM V3 to baseline maturity by site and prioritize investments toward Level 3–4 capabilities that make AI viable.10

The Life Sciences Signal Is Clear

Across BioPhorum’s programs, manufacturers and suppliers have already articulated a shared vision. The MES of the Future manifesto and follow‑on papers call for open integration,27 understanding the priority data,28 and cloud‑ready delivery.26 In 2025, BioPhorum published its Industry Challenges and Enablers paper,32 highlighting seven challenges with directional metrics to cut time‑to‑value and enable near‑real‑time release, to create a pragmatic playbook for change.33 I have been fortunate to help lead this conversation through BioPhorum’s IT Digital and Data Phorum and the MES of the Future workstream, facilitating workshops and publishing with members to translate concepts into action.

A Call To Leadership

The move to a data-centric position is not a technology question. It is a leadership one. The architecture is known. The standards exist. The cloud delivery model is proven. What is missing is the decision to stop hard‑coding business value into siloed applications and to put data at the center of our digital transformation projects.

The message to the C‑suite at MES suppliers and integrators is that the market will reward those who show the entrepreneurial courage to cross the chasm from product‑centric to data‑centric platforms. Research on the 2040 factory vision describes that end state as one having hyper‑automated, AI‑orchestrated operations.30 That will not happen without the data foundation.

Let’s stop building shinier wrappers for yesterday’s MES and start building the data‑first platforms that enable adaptive plants, faster tech transfer, and safer, more reliable supply for patients.

References

- Will O365 only support subscription based licensing starting from 2020? https://afi.ai/blog/o365-licensing-subscription-vs-perpetual

- HOW TO ELIMINATE 5 COMMON ERP AND MES UPGRADE CHALLENGES https://conperio.com/wp-content/uploads/2025/03/10150_5_ERP_MES_Upgrade_Challenges.pdf

- Microsoft lifecycle policy https://learn.microsoft.com/en-us/lifecycle/faq/office

- Perpetual Microsoft Office Licenses vs Subscriptions https://licendi.com/en/blog/microsoft-office-perpetual-licenses-vs-subscriptions/

- How Data Fabric Can Optimize Data Delivery www.gartner.com/en/data-analytics/topics/data-fabric

- Computer Software Assurance for Production and Quality System Software; Guidance for Industry and Food and Drug Administration Staff; Availability www.federalregister.gov/documents/2025/09/24/2025-18468/computer-software-assurance-for-production-and-quality-system-software-guidance-for-industry-and

- IPSE GAMP https://ispe.org/topics/gamp

- How Long Do Data Center Servers Last? www.procurri.com/2025/04/24/how-long-do-data-center-servers-last/

- How Long Do Servers Last? www.parkplacetechnologies.com/blog/how-long-do-servers-last-lifespan-expectancy/

- Digital Plant Maturity Model V3 www.biophorum.com/download/digital-plant-maturity-model-3-0/

- Exploring SAP BTP Reference Architecture To Master Multi Cloud And Platform Environments https://sapinsider.org/wp-content/uploads/2023/11/Exploring-SAP-BTP-Reference-Architectures-to-Master-Multi-Cloud-and-Platform-Environments_final-1.pdf

- SAP Big Picture Architecture https://www.sap.com/germany/documents/2025/02/1288d9d0-f57e-0010-bca6-c68f7e60039b.html

- Enterprise Data Mesh www.oracle.com/integration/what-is-data-mesh/

- Enterprise Data Mesh: Solutions, use cases & case studies www.oracle.com/a/ocom/docs/datamesh-ebook.pdf

- Data Mesh: Delivering Data-Driven Value at Scale www.thoughtworks.com/content/dam/thoughtworks/documents/books/bk_data_mesh_excerpt.pdf

- Data mesh: the beginning, revisited www.nextdata.com/our-pov/data-mesh-the-beginning-revisited

- NAMUR Open Architecture www.namur.net/en/work-areas-and-project-groups/focus-topics/namur-open-architecture.html

- VDMA Guide - Interoperability in Industrie 4.0: NOA (NAMUR Open Architecture) https://vdma-interoperability-guide.org/Architekturen/NOA%20%28NAMUR%20%20Open%20Architecture%29/

- Emerson Sees Boundless Automation™ as Industry Inflection Point to Address Data Barriers & Modernize Operations www.prnewswire.com/news-releases/emerson-sees-boundless-automation-as-industry-inflection-point-to-address-data-barriers--modernize-operations-302071572.html

- Rockwell Automation and AWS Expand Cloud Integration to Advance Industrial Manufacturing www.arcweb.com/blog/rockwell-automation-aws-expand-cloud-integration-advance-industrial-manufacturing

- Siemens Xcelerator: Siemens accelerates IT and OT integration with Microsoft for Edge, Cloud, AI and Simulation https://assets.new.siemens.com/siemens/assets/api/uuid:74767be9-e9ba-4094-8c5d-8eec3576226a/HQDIPR202503197125EN.pdf

- Siemens & Microsoft 'Xcelerate' Industrial Connectivity https://manufacturingdigital.com/articles/siemens-microsoft-enhance-industrial-connectivity

- Why it’s time for 'data-centric artificial intelligence' https://mitsloan.mit.edu/ideas-made-to-matter/why-its-time-data-centric-artificial-intelligence

- Top Trends in Data and Analytics for 2021: Data Fabric Is the Foundation https://info.stardog.com/gartner-data-fabric

- Managing data as a product for digital transformation in the pharmaceutical industry www.biophorum.com/download/managing-data-as-a-product-for-digital-transformation-in-the-pharmaceutical-industry/

- Mapping the pathways to MES in the cloud: addressing challenges and unveiling opportunities www.biophorum.com/download/mapping-the-pathways-to-mes-in-the-cloud/

- Unlocking efficiency: a deep dive into MES integration for enhanced biopharmaceutical manufacturing www.biophorum.com/download/unlocking-efficiency-a-deep-dive-into-mes-integration-for-enhanced-biopharmaceutical-manufacturing/

- Navigating the data maze: a practical guide to defining priority data in MES www.biophorum.com/download/navigating-the-data-maze-a-practical-guide-to-defining-priority-data-in-mes/

- Accenture next‑gen manufacturing systems architecture www.accenture.com/content/dam/accenture/final/a-com-migration/pdf/pdf-171/accenture-mom-architecture.pdf

- Rethinking the course to manufacturing’s future www.accenture.com/content/dam/accenture/final/accenture-com/document-3/Accenture-Rethinking-The-Course-To-Manufacturings-Future.pdf

- Digital Plant Maturity Model 3.0 www.biophorum.com/workstream/dpmm-v-3/

- Manufacturing execution systems (MES): industry challenges and enablers www.biophorum.com/download/manufacturing-execution-systems-mes-industry-challenges-and-enablers/

- Welcome to the MES of the future www.biophorum.com/news/welcome-to-the-mes-of-the-future/