Discussing mRNA: Challenges And Opportunities For Scale-Out And Optimization

By Life Science Connect Editorial Staff

The potential for mRNA-based therapies to address a range of unmet medical needs has made improvements to the uncoordinated and inefficient processes seen today a key driver for industry. Promoting greater stability and manufacturability for these modalities hinges on tackling the operational, technical, and supply chain challenges that currently limit their scalability.

In a recent Cell & Gene Live event, Cell & Gene chief editor Erin Harris sat down with J. Andrew Case, head of supply chain – Cell & Gene Therapies at Genentech, and Daniel Getts, CEO and cofounder of Myeloid Therapeutics, to explore the technologies and research approaches being leveraged in the mRNA space. The pair also discussed challenges surrounding raw materials – both quality and supply – as well as the importance of achieving more efficient scale-out and turnaround times for mRNA production.

Matching Delivery Systems With Unique Products

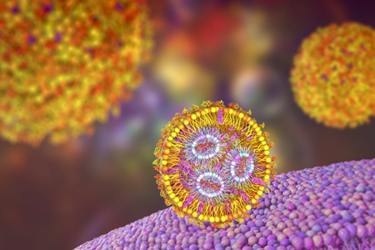

For many of the cell and gene therapies in development today, there remain significant burdens around surmounting the challenges related to their safety, efficacy, and manufacturability. Lipid nanoparticles (LNPs), one of the emerging delivery mechanisms for mRNA therapeutics, pose many of these challenges, including that many LNPs are nonbiodegradable and their interactions with mRNA not well characterized.

According to Getts, at Myeloid, which has demonstrated successful delivery of LNPs encapsulating mRNA for uptake and selective expression by myeloid cells in vivo, some of these issues have been successfully addressed, offering proof of the validity of certain LNPs for other applications. “We're seeing a very strong patent infringement and legal situation going on out there around some of these lipid nanoparticles,” he said. “I think that's because I'm not convinced that there is this broad range of ionizable lipids that are amenable to being used. I think when we go through all of the screening and really appreciate this, there isn't going to be the library that we hope exists, or it may not be as broad.”

When it comes to delivery systems, LNPs are likely to be joined by other systems, Getts added, such as antibody-fused RNA or biodegradable polymers, depending on the needs of a unique mRNA application. “Having worked in biodegradable polymers in the past, they're actually much easier to work with than LNPs, but they have a number of pitfalls when combined with RNA,” Getts said. “I think each product is unique. Each RNA is unique.”

Optimizing And Scaling Raw Materials For mRNA Production

Another key factor in the manufacturability of these products is raw material availability. Raw materials and COGS go hand in hand, according to Case, as the cost of raw materials for these therapeutics is disproportionately large compared to other pharma products. “Part of this can be attributed to the scale component and part to the [dearth of] manufacturers,” Case explained. Because the industry around mRNA is still relatively immature, he said, the resulting lack of raw materials can have an outsized impact on cost and availability as a program scales. “To make something like this requires hundreds of inputs, but it’s a relatively small portion of those products that make up a very large portion of the overall COGS,” he said. To address this, Genentech works with suppliers to improve quality, yields, and efficiency on their end in order to facilitate scale-up for their own products. This push to optimize on the raw materials side is critical, as the quality of raw materials – and any variability in quality from supplier to supplier or batch to batch – can have huge impacts on the quality of a final product.

It's likewise expensive to leverage proven technologies for delivery systems like LNPs, which can leave smaller companies in a position where they are working to juggle royalties effectively, Getts said. This can be further complicated by gaps in understanding within a company itself, Getts added; while there are components of RNA development and manufacturing that are “bucket chemistry,” there are others that are highly unique, which require specialized expertise to get right. “You can’t just take a biologics expert and expect them to just pick up RNA, which is something that I think sometimes happens here,” Getts said.

All of this is combined with the often-long lead times many CDMOs with capabilities related to RNA may have – often, a company with all of their resources in place and ready to start will encounter a six-month or year-long delay in accessing a manufacturing partner’s process development workflow. “These are challenges that we encounter at our scale of business – not necessarily at scale for what we’re making, but our scale of business,” Getts said. For Genentech, Case said, moving toward manufacturing hundreds of individualized vaccines in 2024 as planned will mean fomenting a commercial strategic road map that encompasses plans for production an order of magnitude larger than what is planned. “The industry’s not quite ready for that yet,” he said.

Chain Of Identity And Scale-Out For mRNA

When it comes to ensuring safety and efficacy for mRNA products, another crucial consideration is one that accompanies any therapy manufactured using a patient’s own cells – chain of identity (COI). For certain autologous therapies, such as CAR-Ts, a failure of COI can be immediate and catastrophic, resulting in graft-versus-host disease and death. In the mRNA space, potential mix-ups can be just as deadly, Case said, not because of a patient’s response, but because of their non-response. “If you inject a patient with the wrong RNA vaccine, then nothing will happen,” he said. “That's equally fatal when you're talking about a patient who's an advanced pancreatic cancer patient or an advanced melanoma patient.”

From acquiring a tumor sample to sequencing a tumor to then transmitting that data to a plasmid manufacturer to manufacture the plasmid specific to that vaccine, the COI must be airtight. Once the mRNA is encapsulated, put into vials, and returned to the patient, manufacturers have to establish a protocol that is completely under control and reproducible, so it results in multiple doses over a period of time. “This 360-degree journey of starting with a patient's tumor cells and ending up with a patient being dosed multiple times with a customized vaccine and all the steps that have to take place to ensure that happens correctly is the supply chain challenge for these therapies,” Case said.

Ultimately, there are three key elements to manufacturing mRNA: the sequencing of the tumor, the manufacturing of the plasmid, and the manufacturing of the encapsulated RNA. These elements must be lined up from a scheduling standpoint, which typically requires scale-out in order to accommodate multiple patients in the shortest period of time. “By scaling out, that really means having large classified suites with multiple sets of manufacturing equipment manufacturing these products in each one on an individualized basis,” Case said. “Areas that we're looking at include how many of these process steps can we automate? How many of them can we collapse together into one machine that does multiple steps in a highly precise way that results in a very high success rate in manufacturing? That does them in a way that minimizes the amount of time it takes because turnaround time is critical to these patients?”

Turnaround time is a key element to defining patient access for these therapies, Case added – the longer it takes to manufacture a dose, the lower the chance of actually reaching the patients targeted by these therapies. “Patients don’t have a lot of time in the therapeutic areas we’re currently looking at,” Case said. “You have to develop a robust enough process that connects all of these elements together in the shortest amount of time possible with the highest manufacturing success rate possible that allows you to reach the largest number of patients.”