ARW's Cell & Gene Manufacturing Must-Reads (Classic Literature Edition!)

By Anna Rose Welch, Editorial & Community Director, Advancing RNA

Day-in and day-out, I write, read, listen to, and watch as much content as I can about C&G therapy manufacturing, in particular, and/or other C&G industry-related topics that you should at least be aware of in the manufacturing facility. Every two weeks, I compile the articles and industry updates I think are most worthy of your time into an unconventional newsletter format (below) and send them out via email. But inboxes can be shifty places. (Cue George Carlin on “Losing Things.”)

So, here’s a “permanent” copy of my C&G Manufacturing Must-Reads newsletter that was delivered on April 21 for all you practical people who, like Carlin, abhor the question, “Where is it?

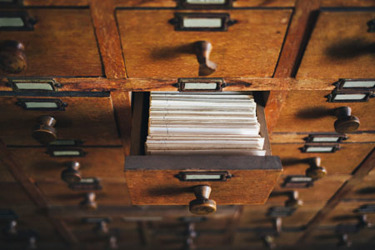

It was extremely tempting to use the April 21st edition of these C&G Manufacturing Must-Reads to celebrate “International Pizza Cake Day,” which I didn’t know existed but the mere sight of which has transformed my life. However, after much deliberation, I decided to play with the equally unsung “Thank You For Libraries Day” theme. Below, each section of articles includes a quote and several not-so-subtle references to classic works of literature you’d likely find in all of these glorious libraries. [The answers are at the bottom😉]

“[CGT industrialization] is 93% perspiration, 6% electricity, 4% evaporation, & 2% butterscotch ripple”

- The biotech world is no stranger to silos — both across the industry and in each company. That’s why I really enjoyed my conversation with Tenaya Therapeutics’ CEO, Faraz Ali. As manufacturing employees started flooding into the company faster than a molten chocolate river, Ali shared what structures the company put in place to ensure the R&D and manufacturing teams weren’t greedy with their knowledge and learned how to speak and respect each other’s equally important languages.

- A golden ticket to see the fantastic spectacle of each company’s vastly different CGT manufacturing paradigm will hardly standardize the industry. As with my previous article, I loved writing about this Kite supply chain exec’s set of ingredients for improving the industry’s manufacturing transparency and fostering greater industrialization.

- We all know that CGT manufacturing requires an entirely new operational model. Luckily, this article treats us to the stage-appropriate tactics to address/prevent the most common manufacturing issues and improve overall industry standardization.

- Speaking of the continuous processing operating model (which we currently don’t employ here in Wonkaville…), pharma can talk about, write, and publish information on continuous manufacturing tech advances until it turns blue in the face. But because this knowledge remains scattered and/or inaccessible, USP and NIPTE have announced a new digital knowledge center to unite all available academic, industry, and regulatory publications on CM advancements.

“Sometimes, I’ve believed as many as six impossible things before breakfast!”

- Sometimes, you can drink unidentifiable liquids labeled “DRINK ME” and eat cakes or mushrooms to grow or shrink. But to my knowledge, none of that was necessary for Penn researchers to shrink the CAR-T therapy manufacturing time down to 24 hours.

- Their preclinical research, published in Nature Biomedical Engineering (open access!), demonstrates that quality over quantity of CAR-T cells matters more when it comes to efficacy.

- This novel’s protagonist says it best: “When I read fairy tales, I fancied this kind of thing never happened, but now here [the CGT industry] is in the middle of one!”

“Every day confirms my belief in the inconsistency of [the CGT manufacturing paradigm]”

- It’s a truth universally acknowledged that a CGT company in possession of unique scientific ideas must be in want of a cost-effective and streamlined manufacturing paradigm. Lo and behold, from across the misty field, BioPhorum strides forth and offers up this informative webinar on their CGT process maps.

- I dare say, if two documents could ever compare to the vision of Colin Firth emerging from a pond in a wet white tunic, it would be these process maps [free registration required]:

- Cell therapy process map

- Gene therapy process map

- These maps spell out the proper manufacturing “etiquette,” if you will, so scientists and engineers can communicate about, coordinate, perform, and improve each process in dignified and socially acceptable ways.

- If your dance card still isn’t full, allow me to introduce you to Standards Coordinating Body. Here’s a list of their current (and recruiting!) working groups and publications. As of March, they’re also one of BioPhorum’s dance partners.

- The SCB most recently waltzed across my LinkedIn feed with their announcement that NIST had launched a new cell counting evaluation tool (COMET) to support Part 2 of ISO’s 2-part cell counting standard, which SCB helped support.

- Keeping your dance partner at an arm’s length may be proper fashion in a minuet, but I wouldn’t advise keeping these SCB sector calls and calls-to-action at a distance.

“It is the easiest thing in the world for [an FDA guidance] to look as if [it] had a great secret in [it]”

- What do CGT CMC experts and whalers have in common? They both know what it’s like to be standing on a rocking boat on a similarly unstable peg leg. To ARM’s Michael Lehmicke, recent CMC stumbles may, in part, be due to a lack of FDA guidance and communication on late-stage CGT development.

- This recently published opinion piece from the FDA’s Peter Marks has been hailed as a new prophecy on the future migrations we can expect in gene therapy development. But really, the manufacturing portion of this editorial is a familiar refrain, harkening back to the goals of the long-in-the-works Bespoke Gene Therapy Consortium (BGTC).

- For more on the BGTC, check out my coverage in this “Must Reads” edition from last November.

- Though the industry lobbed harpoons and ruthlessly pierced holes in the FDA’s 2016 draft guidance on quality metrics data, the agency still has plans to implement (yet-to-be-defined) quality management “ratings” for manufacturing sites. (This would be a separate assessment from CGMP.)

- In May, FDA will be hosting a two-day workshop on its quality management metrics (QMM) progress to-date, lessons-learned from its ongoing pilot program, and its long-term goals.

- Just as killer whales have their own individual and identifying dorsal-patch markings, so too, the FDA hopes site quality ratings will serve as a competitive differentiator for products and manufacturing sites.

Answer key:

- Section 1: Charlie & The Chocolate Factory, Roald Dahl

- Section 2: Alice’s Adventures In Wonderland, Lewis Carroll

- Section 3: Pride & Prejudice, Jane Austen

- Section 4: Moby Dick, Herman Melville