A Versatile Suspension-Based Platform For The Manufacturing Of AAVs

By A. Yousef, M. Langhauser, A. Schulze, A. Schoberth, F. Sonntag, M. Hoerer, K. Heller

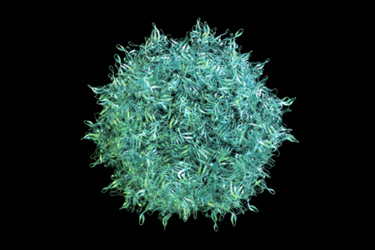

Recombinant adeno-associated virus (rAAV) is a widely used viral vector for gene therapy, but its manufacturing faces challenges due to high demand and limited capacity. Scaling up the process impacts both cost and product quality, and variations between AAV serotypes further complicate development. We present data on yield and impurities for common AAV serotypes at different bioreactor scales, using our proprietary split two-plasmid platform. Our expanding database demonstrates the platform’s broad applicability across serotypes.

Our modular platform offers flexibility, streamlining process development and scale-up, while reducing costs. It minimizes batch variability, builds quality into the product by design, and adapts to specific product needs. Through high-throughput scale-down models, it improves flexibility and reduces complexity, lowering cost of goods (COGS).

This end-to-end solution, optimized for high vector yield and quality, aligns with evolving regulatory requirements while offering adaptability for customer-specific needs. Our commitment is to advance AAV gene therapy, focusing on safety and CMC to make gene therapy accessible for patients with high-risk, common diseases.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Cell & Gene? Subscribe today.